ABOUT THE DEPARTMENT

We are a multi-device lab, integrating all Bioprinting/Biofabrication Technologies and Expertise in one facility. We serve as a resource center for DoD/Federal Investigators and Public/Private Collaborators.

Our Tools

- Biological Laser Printing (BioLP) (high res cell and microorganism printing)

- Extrusion systems (low res cell and hydrogel printing)

- Multitool platform

- Electrospinning (nanofiber tissue scaffolds and biopaper)

Providing translational medical solutions for Military Medicine and Global Health

BIOMATERIALS

BIOINKS

Bioinks are materials that mimic an extracellular matrix environment to support the adhesion, proliferation, and differentiation of mammalian cells. Naturally derived, they can be made of such substances as collagen, fibrin, alginate, polycaprolactone, and thorbin. Among other differences from 3D printed materials, bioinks are printed at 37 °C or below, bioactive, cell manipulable, have mild cross-linking conditions, and must account for cell viability.

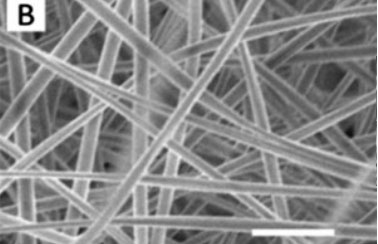

BIOPAPER

Biopaper is biodegradable electrospun gelatin, has high tensile strength, and is ideal for elastomeric tissues. Its binding motifs allow for cell attachment, and is biodegradable through cell-secreted enzymes which allows for direct bilayer cell-cell contact. It has tunable pore size, elasticity, degradation, and mechanical properties allowing it to create both soft and hard tissues. Micro-alignment allows for high resolution inter-layer registration of printed structures. Biopaper also provides scaffolding for low volume print applications.

Applications

- Regenerative medicine

- In-vitro model tissues for drug testing, bioreactors, and biomolecular production

- Preformed cell culture substrates for biological research, including 3D conformal cell printing (e.g. BioLP, droplet, extrusion)

image: Hood, et al. Molec. Cell. Proteomics, 4, 1741-1753 (2005).

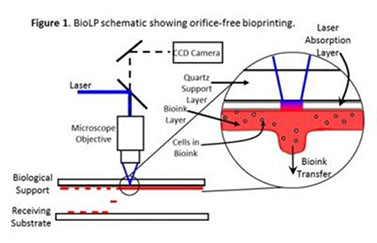

BIOLP

BioLP is a non-contact, orifice-free method of bioprinting with the demonstrated ability to create micron-scale patterns of living cells and biomaterials. BioLP was invented and patented by NRL and can print cells and biomaterial at high resolution in a sterile environment. Utilizing high frequency laser pulses, bioink droplets can be deposited at speeds of up to 500-1000 droplets per second.

This versatile bioprinting instrument creates heterogeneous 3D cellular constructs with single-cell resolution - higher resolution than other commercially available bioprinters, including both extrusion and droplet systems. It also has spot to spot reproducibility and no changes to gene expression of surface markers of printed cells.

(U.S. Patent Nos. 6,805,918; 6,815,015; and 7,294,367)

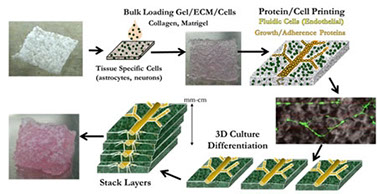

EXTRUSION

Extrusion-based bioprinting systems dispense continuous filaments of bioink, consisting of cells mixed with hydrogel, through a micro-nozzle to fabricate 2D or 3D structures. By altering the crosslinking degree and method, the mechanical properties of the bioink can be tailored to specific printing parameters and tissue types. This method has low resolution and can be slow, but it has no limitation on cell density, can print a wide variety of bioinks, and is reasonably cost effective.

Applications

- Create engineered tissues and organs with the potential to provide replacements for diseased or damaged organs, solving the shortage of donor organs.

- High throughput in vitro engineered tissues (blood-brain-barrier, liver, lung, gastrointestinal, etc.) for drug discovery and/or toxicity screening.

MULTITOOL PLATFORM

The multitool build platform combines multiple printing technologies, including bioLP and extrusion, on one machine. By including these technologies on the same platform, the advantages of each can be fully utilized, while the drawbacks can be mitigated by employing a different printing modality. For example, large features can be fabricated with extrusion printing, while individual cell locations can be addressed with BioLP. Furthermore, the 5’ x 5’ travel area allows for the addition of new printing technologies as they are developed by 4D Bio3 and their collaborators.

BIOREACTORS

The bioreactors are biocompatible and customizable for specific use, including microscope, blood brain barrier, lung, and microbiome uses. With integrated components like internal sensors and fluid flow, we can expose tissue constructs to physiologically relevant forces and monitor their response in real-time. Bioreactors can be fabricated with 3D printers, allowing for the inclusion of internal channels and constant fluid flow.

ELECTROSPINNING

Electrospinning is a method for depositing nanometer wide strands of biological polymers, such as collagen or gelatin. As the process progresses, the nanometer strand form a fibrous matrix for cell attachment, similar to what is observed in native tissue. This method can be tuned to create mats that match the mechanical properties for different tissues (brain vs lung) and amenable to high throughput (drug development).

Ocular Program Applications

- Direct write electrospinning of collagen and synthetic polymers

- Applications include simulated cornea for surgical training of military ophthalmologists

- High speed processing will allow formation of complex microstructure within practical time limits

MICROSENSORS

The microscale sensor network self-organizes for readout of the localized tissue status allowing for real time monitoring and results.

Applications

- Readout of the position of surgically manipulated tissue

- Temporal change in biomarkers within 3D printed drug development tissues

- Low power body area networks

- Readout of tissue parameters such as glucose or neuronal activity